We built our own equipment to identify and discard low-quality beans. Before every batch, we remove beans that are flat, punctured, moldy, too large, too small, and poorly-fermented.

We built our own equipment to identify and discard low-quality beans. Before every batch, we remove beans that are flat, punctured, moldy, too large, too small, and poorly-fermented.

That's our motto.

Removing beans of lesser quality greatly improves the final flavor of our chocolate. If you’re curious to learn how we do it, check out our process below.

That's our motto.

Removing beans of lesser quality greatly improves the final flavor of our chocolate. If you’re curious to learn how we do it, check out our process below.

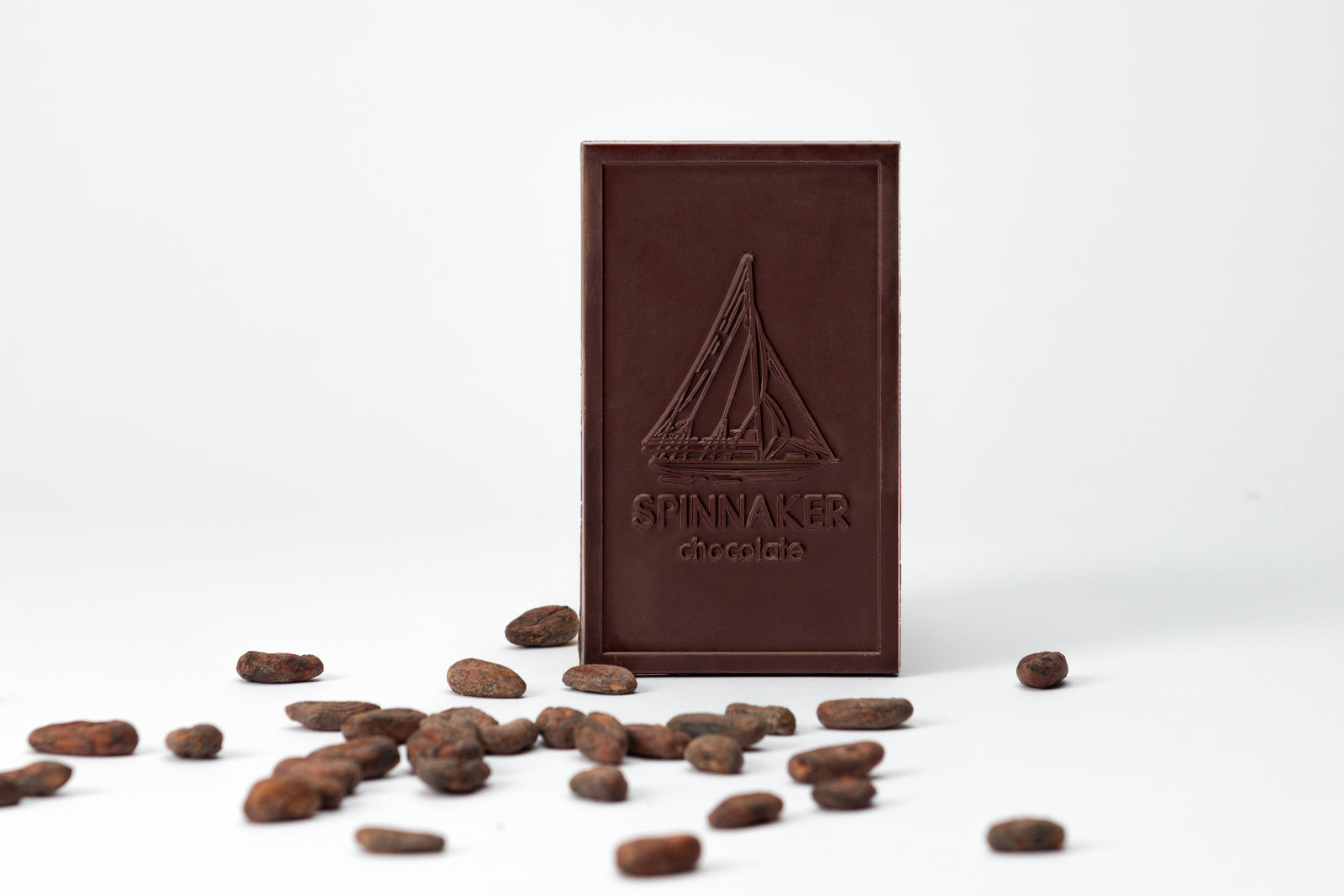

The best ingredients make the best chocolate. We start with the best cacao we can find. We source from countries all around the world, like Madagascar, Uganda, Trinidad, Ecuador, and Nicaragua to name a few.

Transparent—and often direct—trade. We purchase all of our ingredients through a transparent supply chain. It's important to us that the cacao, sugar, and dairy farmers we work with are adequately paid. When we don't buy directly from a farm, we work with importers who share the same values.

Sorting systems we built in-house. Imperfect beans are picked out first. Unripe and poorly-fermented beans are discarded second. We start with beans of the highest quality and only the best of the best make it into the final product.

Beans vary dramatically in size and moisture content. Roasting with whole beans generally means over-roasting some and under-roasting others. Instead, we remove the shells first and roast only the nibs, which gives us better consistency and flavor development from roast to roast and batch to batch.

Stone-ground to the ideal micron size. Above a certain grind size, chocolate tastes gritty. Below a certain grind size, it tastes gummy. We target the ideal micron range for a smooth mouthfeel.

Conched at the proper temperature. Raw cocoa is full of overpowering astringency. We apply heat during the conching process to bake off excess volatile aroma—leaving only the natural flavor of the cocoa.

Chocolate has six crystal structures. The proper sequence of heating, cooling, and heating again sets each bar in the perfect, melt-in-your-mouth, crystal structure.

Biodegradable, compostable, or recyclable. We’re tired of seeing trash floating in the ocean, so we’ve made it a mission to reduce waste wherever we can. From our tape, labels, and boxes to our shipping insulation and bar wrapper, our packaging is compostable, biodegradable, or recyclable.